Today, we will talk about Why are blueprints blue? What is the purpose of a blueprint? when I think about blueprint printing, it is said that the cost of this kind of drawing is lower than that of direct printing, and the storage time is longer. But now we use CAD.

The electronic files are kept longer and the cost is not high. I searched the Internet to find out. I don't know whether there is such a practice in the developed countries of formal enterprises and the machinery industry.

Why are engineering drawings and mechanical

drawings blue? You may know that the word blueprint comes from this. I didn't

know why the drawings should be blue before. I couldn't restrain my curiosity.

I need to know.

In fact, the reason why these drawings are

blue is related to their drawing methods. These drawings are not drawn or

printed, but "sun-dried". Maybe in the streets, there are always some

signboards like sun print pasted on the door of the printing agency, which

refers to this.

The drawing was originally drawn on sulfuric

acid paper, which is a kind of translucent paper. When drawing, a needle pen, and ink should be used. Of course, many of them don't need to use a needle pen

to draw, because CAD can directly draw and print on sulfuric acid paper.

But

when we went to school, we learned how to use a needle pen to draw on sulfuric

acid paper. It seems that we want students to retain some basic skills. But to

be honest, my pen has been used so many times. What I drew are the drawings that

I handed in as my homework. Maybe the course won't exist in the future.

The drawings drawn on sulfuric acid paper

can't be used directly because it's very thin and easy to break. He is just the

base map, with which many copies can be made.

Printing also requires special paper. This

paper is different from the white paper we usually use. It has been chemically

treated (see below for details), just like the negative in the camera.

When

printing, place the sulfuric acid paper and the drying paper on top of each

other and expose them to the sun so that the paper will be exposed to the

sun. The places with patterns on the sulfuric acid paper will block the sun so

that the paper will not be exposed to the sun.

The basic principle of sunning is

that the chemicals on the sunning paper will react with the sunlight and the

color of the place where the light is shining is different from that where it

is not.

Such a picture is ready for sun exposure. The reason why the picture is

blue is that the complex reaction between Fe2 + and red blood salt is blue. The

modern printing machine can directly complete this seemingly complex process and can produce drawings in batches.

Some people want to ask why they have to work

hard to print a picture. It's OK to print it directly. Of course, it's not

impossible to print directly, but because architectural drawings and mechanical

drawings generally need a lot of points, the size of the drawings is large,

and the number of copies is large.

If you print directly, you need a larger

machine, and the cost is relatively high, and the large-scale printing copier

is also emerging in recent years. And print will be much cheaper, and as long

as a set of the sulfuric acid paper base can be used many times.

The blueprints are

also of good quality, easy to store, and will not be blurred by fading for a

long time. Therefore, in general, there is no urgent need, or the cost of this

method is lower.

How are Blueprints Made?

Method of drawing production and blueprint

Blueprints, commonly known as

"blueprints", are a kind of chemical coating processing paper, which

is specially used for various engineering design and mechanical manufacturing

blueprints. It is an essential article in production, scientific research, and construction.

Contact local cultural goods stores to produce and sell blueprints, or

simply use blueprints to open stores to undertake blueprints services. There

are few operators in various regions, and the undertaking of this industry

should be very prosperous, and good economic benefits can be obtained.

(1) Type and specification of drying drawings:

Due to different paper bases, the sun drawings can be divided into two categories: special size and No. 1. The special size base paper is 90g or 80g, and the sun drawings produced are used for making materials that need to be kept for a long time, for supplying for export, or for delaying external engineering drawings. No. 1 draw is 80g, which is used for general printing. Most areas in China use No. 1 printing.

There are two specifications for drying drawings: flat plate and drum. The

national width of the drum is 88 cm. In order to meet the special needs of

individual units, there are also two kinds of production widths of 93.63 cm.

Each roll has a length of 50 or 100 meters. Some parts of the flat-drying

drawings are called technical papers. The standard specifications are: No. 0 is

841 × 1189 mm (fully open), No. 1 is split, No. 2 is 4, No. 3 is 8, and No. 4 is

16.

The use methods for drying drawings are as follows:

- (1) Wet drying, that is, water washing and drying, that is, iron salt drawings, the photoreduction of which is water washing, some units still use this method.

- (2) Dry drying, i.e. diazole addition drying, or ammonia fumigation drying is used for light-sensitive reduction, which is supplied domestically.

- (3) There are two kinds of semi-wet drying drawings, one is to apply a photosensitive agent and reducing agent on the paper, while a photosensitive side couple to synthesize the drawing, which is not available in China; the other is used for dry drying, when printing, the ammonia water is evaporated to form fog so that it can be dried while forming the drawing.

From the line color, there are:

- (1) Blueline on white background, white line on a blue background, brown line on white background, and wet drying drawings.

- (2) Blue background purple line, white background brown line, and white background black line are used to dry drawings. At present, most of them are blue and purple lines, and some areas have blue lines or black lines with white backgrounds.

From the coated surface: there are two kinds of single-sided coating and double-sided coating:

- (1) One side coating has two meanings: one is to only apply the photosensitive solution on the used paper; the other is to apply a photosensitive agent on one side and borate water on the other side to eliminate the warpage of paper and improve the storage period. In fact, it is applied on both sides

- Cloth, because of only one side sensitivity, is also known as one-sided coated shoes, most domestic areas are of this type.

- (2) Double-side coating is both sides are coated with a photosensitive agent, and both sides can print, mainly to reduce the volume of information and save paper. At present, there are 19 places in China, such as Shanghai, Beijing, Tianjin, Hangzhou, Nanjing, Wuhan, etc., which produce blueprints.

In recent years, the development direction is white

background blue line and double-sided coating. Because blue line blueprints are

1 / 5 faster than the purple line when the preservation time is not changed, the color is bright, and the speed of sensitivity tolerance is large.

(2) Raw materials and manufacturing of drying drawings:

The raw materials are composed of base paper and photosensitive coating. The quality of the base paper and the proper preparation of coating directly or indirectly affect the use efficiency and shelf life of finished products. It is required to use kraft or sulfite wood pulp, long whisker grass pulp, cotton bamboo, or rag pulp, with the appropriate amount of combustible fillers, to make the base paper with a long web machine.

The paper is white and tough, without black spots and wrinkles, uniform

thickness, consistent tensile force, strong water resistance, and no

permeability. The paper should be slightly acidic, and should not contain reductive

and oxidizing ingredients.

The coating is divided into the diazo-sensitive coating

and iron salt-sensitive coating. Diazo photosensitive coating: RT is not

sensitive material; R salt photosensitive raw material is used as an intermediate

coupling agent to help color; oxalic acid is stable for the first two

photosensitive raw materials; aluminum sulfate keeps the blue stable.

In

addition, there are gum, acid paste blue, and other auxiliary materials. Iron

salt photosensitive coating: ferric ammonium citrate is the main photosensitive

agent; red blood salt (iron cyanogen potassium) is the main color-developing

agent; auxiliary raw materials are gum, etc.

The production process is based on paper - coating formula - drying - Inspection - packaging. The whole process

must be carried out in a dark room, using a red light bulb. The coating method

can be a simple manual brush coating or roller mechanical coating.

Using an iron salt photosensitive coating to

make blueprints can be carried out simply, and its formula can be in the

following four proportions:

- Liquid A: ammonium ferric citrate 1 point, water 4 or 5;

- Solution B: 1 part of potassium ferricyanide, with 6 or 5 water.

During manufacturing, dissolve the above two

substances in a certain proportion of water in the darkroom, and hide them in a dark place in a brown glass bottle with a plug, so as not to expose them; then,

tighten the tough and smooth fine cleaning paper (for example, the flat sheet

shall be nailed with a picture nail, so as to brush and apply for the liquid

medicine evenly on the hand).

Install the roller machine; mix the liquids A and

B by 1:1 and then filter them to prevent damage caused by the precipitation of

potassium ferricyanide; after mixing the two liquid solutions, they can't be

put in, so they should be coated on the paper immediately after filtering, or

evenly coated back and forth with the liquid medicine dipped in the pen and

cotton, paying attention that they can't be coated too much or too little;

finally, they should still be put in the darkroom to dry, and be inspected and

cut;

Then roll into a cylinder in the darkroom, use plastic paper, wax-coated

paper, moisture-proof paper, and kraft paper with a total of four layers, then

use wooden boxes or corrugated boxes with more than five layers, lined with

moisture-proof paper, 6 or 4 volumes in each box, and use an iron sheet or plastic

tape for external use to form two vertical and two horizontal hoops, then leave

the darkroom, store the anti-light and anti-alkali drugs in a ventilated and a dry place with a temperature of no more than 35 degrees and a humidity of no

more than 85% Dry, 30 cm above the ground.

(3) Blue drying method:

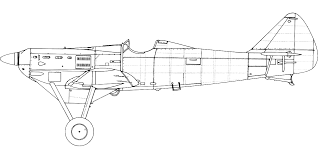

- (1) Use an ink pen or drawing pen to describe the drawing on the glass or transparent and translucent paper (photo negative is also acceptable), and then put it on the drying paper. Use a glass or glass frame to clamp the drawing and the drying paper tightly without loosening.

- (2) Move it to the sunlight for 10 minutes to 1-2 hours (according to the sunlight intensity and operation experience), and then move it into the room to take out the sun drawing.

- (3) Immediately immerse the sunning drawing in the cold water for 3-5 minutes, or put it into the water with a little 1% diluted hydrochloric acid for rinsing, the effect is better.

- (4) After washing and drying, a clear blue background and white line blueprint appear. The principle of this process is: under the action of light, ferric ammonium citrate is reduced to ferrous ammonium nitrate, which reacts with red blood salt (potassium ferricyanide) to form a blue ferric ammonium cyanide salt insoluble in water and precipitates on paper, while the part that is not exposed to sunlight or has no reaction is dissolved in water and washed away.

In this way, the blueprint can also be transformed into images of other colors. For example:

- (1) 1. Turn it into the brown image, you can submerge the suntanned blueprint in dilute ammonia water, and the image will gradually disappear. Wash it with clear water, then submerge it in dilute tannin solution or cold tea water, and the image will return to brown or purple-brown.

- (2) Turn into the purple image, that is, dip the blue image into a borax solution or lead acetate solution and the image becomes lavender.

- (3) Turn it into a green image, then dip the blue image into a strong acid ferrous sulfate solution (add 40 parts of 1.5% ferrous sulfate solution into 1 part of 6m sulfuric acid solution to form the immersion image solution), the image will turn green, take it out, wash it with water, and then dry it.

*** Please Share These Resources with Colleagues, Friends, and Family ***